Summary of information:

Profiled sponge refers to the sponge which is pressed into different shapes according to its...

Profiled sponge refers to the sponge which is pressed into different shapes according to its use in production and processing, so as to distinguish it from the traditional square sponge. It has many advantages, such as water-proof, moisture-proof, heat preservation, recycling and so on. It can not only save the operation cost of large-scale enterprises, but also better deal with the environmental pollution problems presented in the industry. What types of heterogeneous sponges do they have?

1. Rubber wool. One of the sponges, which is foamed with latex as the main material. It has the characteristics of rubber, good elasticity, good resilience and no deformation, but its price is high, which is 3-4 times higher than that of foamed cotton.

2. Shaping cotton. This material is made of polyurethane material, mixed with various additives such as foaming agent, pressing agent into a simple mold to heat up. It is suitable for swivel chair, sofa cushion and back, and a small amount of armrest is also made of shaped cotton. At present, the material density is 55-60, and its elasticity is in line with the relevant national standards. The elastic hardness of sponge can be adjusted according to different parts of the product. Generally, the base cotton has higher hardness and higher density, followed by the back cotton and the soft cotton.

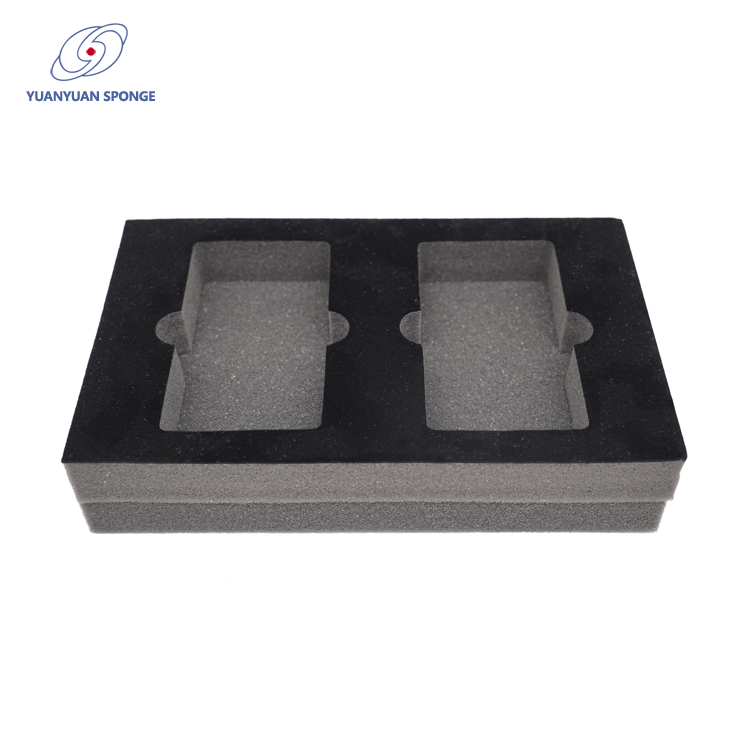

3. Slow rebound sponge, also known as high load-bearing sponge. This material has good cushioning and absorbing impact force and good protection, good shock absorption and temperature resistance, density, hardness and rebound time can be adjusted according to the needs. It has good protection, good shock absorption and temperature resistance. Density, hardness and rebound time can be adjusted as required. It is widely used in household and electronic equipment packaging. The color (gray, white, yellow, etc.) and density (35-80) can be added in the foaming process to improve the properties of the sponge.

4. Foam foam. This material is foamed with polyether, just like foamed bread. It can be foamed by mechanical equipment or manually surrounded by wood. The foamed sponge is like a square loaf. After slicing with a slicer, the thickness of the foam can be adjusted according to different requirements.

Heterogeneous sponge can disperse external noise and reduce the volume of noise. It has a great effect on people's life and enterprise development. Because of its good anti-static properties, it is generally used to process small mechanical equipment and improve the power of enterprise operation.